- -10%

- Save 10%

GET REWARDS WITH DTF TRANSFERS NOW

Earn a reward after creating your account on the site.

More info? click on the button below

GET REWARDS WITH DTF TRANSFERS NOW

Earn a reward after creating your account on the site.

More info? click on the button below

Same-Day Shipping Available – Enjoy Free Shipping on Transfer Orders Over $99

Maximize your design potential with our stunning, custom DTF gang sheets.

Choose the size, upload the design and wait for it to arrive.

Our innovative Flexible Peel Technology allows you to Peel Hot or Cold, making application incredibly easy!

Combine multiple graphics in a single order. Perfect for personalized apparel and accessories.

Our high-quality transfer film delivers vibrant, durable prints that withstand multiple washes.

Use our free gang sheet builder.

First time ordering? Get 50% Off with coupon 50NOW

Need your DTF order fast?

Check out our Same-Day Shipping Add-On

⚠️ Not for use on sublimated jerseys. Applying DTF transfers to sublimated garments may lead to dye migration, affecting print quality.

1-2 business day processing time

Shipping options

Same Day Print: $35 Prioritize your order for printing on the same day (order must be placed before 12 PM EST

Free delivery

Free Delivery on Minimum Amounts!

Free ground shipping for orders over $100 - GroundFree

Free 2nd Day Shipping for orders over $300 - 2ndDayFree

Free Next Day Shipping for orders over $500 - NextDayFree

Please upload your artwork after your purchase!

Our Guarantee

We are proud of our products and offer a satisfaction guarantee on all our DTF transfers. If you encounter any issues with your order, let us know, and we’ll promptly replace them free of charge.

100% satisfaction guarantee!

A gang sheet is a creative printing method that allows you to combine multiple designs on a single film. Rather than having individual custom heat transfers for each logo, name or graphic, you can combine them more efficiently on one sheet to save time, materials and money.

In short, these layouts mean efficient printing, reduced waste, lower costs per design and shorter production times. From brand logos to custom apparel and promotional merchandise, we can help you optimize your processes and utilize all available print space.

Based in Miami, Florida, we offer local collection and nationwide shipping, making us the ideal choice for those searching for DTF gang sheets near me.

Want to know how many designs can fit on one sheet? As with anything, this varies based on design sizes and sheet dimensions However, our free online builder allows you to preview your layout before placing an order, so there's no guesswork involved!

Boost your profits and printing possibilities with our premium heat transfer films from DTF Transfers Now!. Our quality films allow you to print numerous designs on a single sheet, making them ideal for high-volume businesses, creators and resellers seeking affordable, professional applications.

Not sure whether to choose gang transfers or individual heat applications? Here's a quick comparison to help you decide:

| Feature | Gang Sheets | Individual Transfers |

| Cost Efficiency | ⭐⭐⭐⭐⭐ Save up to 70% | ⭐⭐⭐ |

| Multiple Designs | ⭐⭐⭐⭐⭐ Print many designs at once | ⭐⭐ One design per order |

| Space Optimization | ⭐⭐⭐⭐⭐ Maximize material usage | ⭐⭐ Fixed size per design |

| Production Speed | ⭐⭐⭐⭐⭐ Fast batch production | ⭐⭐⭐ Individual processing |

| Customization | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ Limited to one design |

| Material Waste | ⭐⭐⭐⭐⭐ Minimal waste | ⭐⭐ More unused material

|

Multi-design printing are ideal for businesses that need to print various designs in small quantities. Individual prints are ideal for large quantities of a single design.

We at DTF Transfers Now are Miami's premier heat transfer specialists. We offer a quality service that will make your business stand out in this busy market.

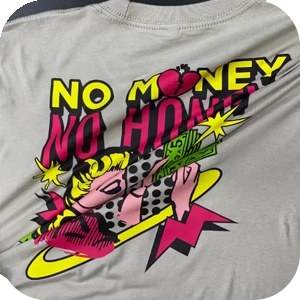

Our films utilize advanced printing technology to produce stunning vibrancy and depth in every design. Every bold character and intricate graphic is captured in stunning color and detail.

The press, peel, and remove technique saves valuable production time. Unlike vinyl cutting, our sheets don't require residue removal.

To enhance flexibility, our prints can effortlessly adapt to both hot and cold peel techniques.

Designing your layout is easy with our intuitive online builder. Upload, organize and optimize your space — all in just a few clicks.

Our heat applications endure numerous washes without fading. This is thanks to premium inks and films that are soft to the touch yet maintain their appearance after each wash.

Our sheets work on virtually any material, including cotton, polyester blends, and denim. These heat press applications are permanent, regardless of fabric type or color.

There are zero minimums and no setup fees, so you can order exactly what you need, whether that's one sheet or hundreds for big projects. There are no minimum requirements and no hidden setup costs.

Need it quickly? Same-day printing is available for an additional fee. Plus, enjoy free shipping on all orders over $99. Live in Miami? Our convenient pickup service is available for local customers.

As a family-owned company with over 25 years' experience, we provide Miami-standard craftsmanship and dedicated US-based support. We're dedicated to your success, offering dependable turnaround times, knowledgeable guidance, and outstanding quality for each order.

Whether you are placing your first order or are a frequent customer, our Miami production facility uses state-of-the-art technology and high-quality materials to guarantee results that surpass expectations.

Getting started with our premium direct-to-film printing is easy. Here's how to order your multi-design layout:

Our sheets range from 22" x 6" to 22" x 300". Select the dimensions that best fit your designs and project requirements.

Now, proceed to checkout to finalize your purchase. Your order details will be saved, confirming your heat transfer sheet reservation.

Need a sheet? Use our free Builder to create the best layout. We recommend using high-resolution PNG files without backgrounds.

Upload your artwork in PNG, PDF, or AI format. For the best quality results, we recommend 300 DPI with a transparent background.

Each sheet is professionally printed for maximum durability. We process orders quickly and ship within 24-48 hours.

Achieve perfect results every time! Read our essential guide to heat press application, compatible materials, and product customization below.

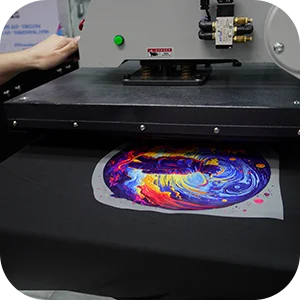

Place your garment on the heat press and press for five seconds. This step removes moisture and wrinkles, ensuring a proper bond.

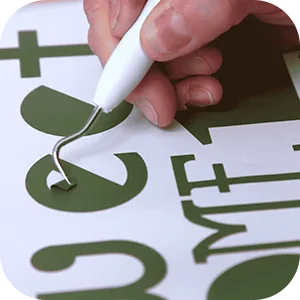

Cut your design from the multi-design sheet, if needed. Place the heat transfer design-side down on the garment so the inked side touches the fabric and the clear film is on top.

Set your heat press to 300°F (149°C). Apply medium to high pressure, close the press, and press for 10 seconds.

Thanks to our flexible peel technology, you can peel the film after waiting 4-6 seconds while it's still warm, or let it cool completely before peeling.

Do you want your design to be locked in and look extra clean? Cover it with parchment paper or a Teflon sheet, and press again for 10 seconds. This will boost wash durability and provide a polished finish.

🔴 Please note: if your design has fine details, we recommend letting the sheet cool completely before peeling.

🧼 Washing Instructions: For maximum durability, wait 24 hours before the first wash. Wash inside-out in cold water with mild detergent. Tumble dry low or hang dry. Avoid bleach.

❓Need more details? Check out our complete guide.

Our Heat press applications are highly versatile and can be applied to a wide range of fabrics. Here's how to achieve the best results with common materials:

⚠️ Important note: Do not apply these heat press designs to sublimated jerseys. Doing so helps prevent dye migration, which can affect print quality.

🚫 Challenging Materials: Applications typically do not work well on fabrics with coatings, such as silicone, water-resistant materials, and certain nylon blends. These coatings can prevent proper adhesion, which impacts print quality and durability. Additionally, fabrics with rough textures or that are highly elastic may not be suitable for these types of prints.

Our highly versatile custom prints allow you to customize an extensive range of products, offering endless creative possibilities. They are perfect for personalizing:

This list is not exhaustive because heat press applications adhere exceptionally well to a wide variety of materials. This makes almost any fabric-based item a potential canvas for your unique designs.

Mastering multi-design layouts allows you to maximize prints and optimize costs. Here, we offer detailed tutorials for preparing designs in popular software programs.

Quickly build your layouts using our free online tool! Follow this easy tutorial.

Ready to design? Use our free builder!

Even if you're a beginner, this tutorial shows how simple it is to prepare layouts in Canva.

Master the process effortlessly with our

Discover tips and tricks for creating perfect layouts in Adobe Illustrator. Learn how to arrange your applications effectively.

Unlock powerful layout techniques. Learn to optimize your designs with our

Use Photoshop effectively for your custom printing projects to save materials and speed up production.

Master layout optimization for custom heat transfer sheets with our comprehensive

Understanding the cost of your multi-design sheets and placing an order should be simple. Here, you'll find details about our transparent pricing structure and streamlined ordering process. You'll also find tools to help you plan your projects efficiently.

Looking for affordable multi-design printing? You've come to the right place! Want to easily purchase quality sheets online? At DTF Transfers Now, we offer outstanding quality at reasonable prices with no hidden costs.

Our pricing is clear and straightforward: depending on sheet size, you pay a set price per square foot. With this simple method, there are never any surprises - you always know exactly what you're paying.

Curious about costs? Use our free calculator to view expenses in real time. Our wholesale program offers substantial savings for larger operations - the more you print, the more you save.

These special offers make it even more affordable to experience the quality and convenience of our printing service!

🎫 50% discount on your first order

Use Coupon Code: 50NOW

🚚 Free Ground Shipping for orders over $100 - Use code: GroundFree

2️⃣ Free 2nd Day Shipping for orders over $300 - Use code: 2ndDayFree

🚨Free Next Day Shipping for orders over $500 - Use code: NextDayFree

These special offers make it even more affordable to experience the quality and convenience of our custom heat transfer printing!

We are proud of our products and stand firmly behind their quality. That's why we offer a satisfaction guarantee on all products. If you encounter any issues with your order, simply let us know, and we'll promptly replace them free of charge. Your complete satisfaction is our priority - we're not happy unless you're happy with your results!

We are proud of our products and stand firmly behind their quality. That's why we offer a satisfaction guarantee on all heat press applications. If you encounter any issues with your order, simply let us know, and we'll promptly replace them free of charge. Your complete satisfaction is our priority - we're not happy unless you're happy with your results!

At DTF Transfers Now, we understand that quality and trust are essential. That's why we offer:

We guarantee vibrant colors and exceptional durability for all of our products

Our team is ready to assist you throughout the entire process, from design selection to application.

We ensure that every order consistently meets the highest standards.

We understand that time is of the essence when working with multi-design printing. That's why we process and ship every order within one to two business days. This ensures that your projects keep moving forward without interruption.

If you need faster results, we offer a same-day printing service for an additional fee to save you time

🔴 Orders placed after the cutoff time will be processed the next business day.

Free (1-2 business days).

$11.99 (1-6 business days).

Rate calculated at checkout.

Concerned about your order status? Once your order ships, you'll receive a tracking number to monitor its progress. If any issues arise, please contact us so we can address your concerns promptly.

Our professional heat transfer films are the perfect solution for every application.

To ensure your designs turn out perfectly every time, it's essential to understand the ideal sizes and best practices for printing. Our comprehensive Size & Print Guide provides all the information you need.

DTF (direct-to-film) technology is an innovative printing method that creates vibrant, long-lasting designs onto specialized film. These graphics are then applied to garments using heat. This printing technology stands out for its exceptional adaptability to a wide range of fabrics, including cotton, polyester, and their blends. It ensures outstanding results on both light and dark textiles..

Is an optimized film that combines multiple graphics in a single space. This setup maximizes use of the printable area, resulting in more efficient production and reduced material waste — perfect for large batches of customized apparel or promotional items.

You can create a multi-design layout with any design program like Photoshop, Illustrator, or Canva.com. Here's how to do it:

- Set your artboard to be 22 inches wide. The length will vary based on how many designs or logos you want to include.

- Set the resolution to 300 DPI, and the color mode is RGB.

- Upload your images to your chosen design program. For the best print quality, use vector images.

- Adjust each logo or image to the needed size and replicate as required.

- Save your layout as a PNG file with a transparent background.

We recommend using high-quality image formats such as PNG, PSD, AI, or TIFF. PNG files are often preferred because of their excellent handling of transparency and ability to maintain crisp detail without creating excessively large files. Vector formats like AI and EPS offer unparalleled scalability, ensuring your designs remain sharp at any size. PSD files are also a good choice for intricate artwork thanks to their flexibility.

Absolutely! Printing various designs on a single layout is not only possible, it's a fundamental benefit of the direct-to-film process. This versatility streamlines production for a wide array of graphic projects.

Our heat press applications are incredibly versatile, working well on a wide range of materials. You'll get excellent results on fabrics like 100% cotton, cotton/poly blends, 100% polyester, polyester blends, tri-blends (for a soft, vintage feel), nylon (great for activewear), leather, and denim. These applications are perfect for personalizing items such as tote bags, caps, hoodies, sweatshirts, and canvas.

However, there are some important considerations:

First, pre-press your garment for 5 seconds to remove any moisture or wrinkles. Then, place the transfer design face down on the fabric, ensuring the inked side touches the fabric and the clear film is on top.

Set your heat press to 300°F (149°C) and apply medium to high pressure (around 60 PSI), pressing for 10-12 seconds.

Important Note for Nylon: Use a lower temperature of 260-265°F (127-129°C). Press for 6-8 seconds and use the same time for the final press. (For Nylon, it's essential to use a silicone sheet instead of Teflon, as Teflon may stick.)

Thanks to our flexible peel technology, you have options for removing the film:

Important Note: If your design has fine details, we recommend letting the sheet cool completely before peeling. This ensures the best result.

Yes, you can use a household iron to apply your transfers. However, for the best, most durable results, we highly recommend using a heat press. A heat press provides consistent temperature and even pressure, both of which are essential for proper adhesion and ensuring that your transfers will last through many washes. Irons simply can't provide the necessary precision for optimal application.

These prints are highly durable and can withstand frequent washing and daily wear. Proper application and care will ensure long-lasting results.

Proper storage is crucial to ensure the integrity of your printed films. Store them flat in an airtight container, such as a sealed plastic bin or heavy-duty Ziploc bag. Maintain a cool, dark, and dry environment to prevent deterioration. Refrain from rolling, folding, or stacking the sheets, as these actions can compromise the heat applications and diminish their quality. An optimal storage climate involves temperatures between 65 and 70 °F (18 and 21 °C) and humidity levels below 50%.

To ensure the integrity and longevity of your printed film, it is essential to store it flat. Avoid rolling or folding, as this can damage the design and adhesive, especially along the edges. Rolling also exerts pressure that can affect adhesion or cause wrinkling. For best preservation, keep your sheets flat in a clean, dry space, away from sunlight and weight.

Orders are processed within 1 to 2 business days. Same-day printing is available for orders placed before 11 a.m. EST for an additional fee.e.

If we haven't started production yet, you can request changes. However, once the printing process has begun, modifications are no longer possible.

We do not offer refunds once an order has been placed. However, we guarantee to replace any defective prints resulting from our error. If you receive a defective print, please contact us and we will work with you to resolve the issue promptly.

Are you ready to order your multi-design layout? Are you ready to reduce expenses and optimize your printing capabilities? Start using our high-quality, personalized solutions today!.

Thanks to our simple application process, you'll be making expert custom clothing in no time! Just upload your designs and select your size. We'll take care of the rest.

Our films provide outstanding results for your commercial or artistic projects, with brilliant colors and flawless adhesion to any fabric.

We are your go-to resource for quality printing. Based in Miami, Florida, we serve clients nationwide. We make it easy to get the high-quality results you need with quick shipping options and convenient local pickup.

👉 Order now and experience the difference that a professional printing service can make for your business!

There are no available reviews. Write your review.

Maximize your design potential with our stunning, custom DTF gang sheets.

Choose the size, upload the design and wait for it to arrive.

Our innovative Flexible Peel Technology allows you to Peel Hot or Cold, making application incredibly easy!

Combine multiple graphics in a single order. Perfect for personalized apparel and accessories.

Our high-quality transfer film delivers vibrant, durable prints that withstand multiple washes.

Use our free gang sheet builder.

First time ordering? Get 50% Off with coupon 50NOW

Need your DTF order fast?

Check out our Same-Day Shipping Add-On

⚠️ Not for use on sublimated jerseys. Applying DTF transfers to sublimated garments may lead to dye migration, affecting print quality.

check_circle

check_circle