A Guide to the Best DTF Transfers of 2024

You're on the hunt for the perfect solution for your creative projects. How can you create products that feature your designs, but are also vibrant and of high quality?

The answer is DTF transfers!

Today we're taking a look at the best DTF transfers of 2024. We'll talk about what you need to know to unlock the potential of DTF technology, ensuring your projects not only meet but exceed expectations.

Keep reading to find out more!

Understanding DTF Transfers>

Direct to Film (DTF) transfers are a modern way to print designs onto clothing and other items. This method involves printing a design onto a special film and then transferring it to the desired surface with heat.

DTF technology is popular because it works on a wide variety of materials and produces colorful, durable designs.

Advantages of DTF over Traditional Printing Methods

DTF transfers have several advantages over older printing techniques. One of the biggest benefits is their flexibility.

Unlike screen printing, which requires a new screen for each color, DTF can create designs with many colors all at once.

This makes DTF great for detailed and vibrant prints. Also, DTF transfers are strong and can handle washing and wearing better than some other methods.

Plus, they stick to a lot of different fabrics, from cotton to polyester. This makes them great for a range of projects.

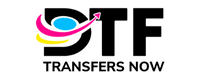

Key Components of a DTF System

To get started with DTF printing, you need a few key pieces of equipment. First, you need a DTF printer. As the name suggests, this is a special kind of printer designed to handle the DTF process.

Next, you need the transfer films that your designs will be printed on. These films are then coated with a powder adhesive, which helps the design stick to the fabric when heat is applied.

Finally, you need a heat press. This tool applies the heat and pressure needed to transfer the design from the film to the fabric.

Getting into DTF printing might seem like a big step. But its ability to create stunning, durable designs on a wide range of materials makes it a valuable tool for anyone looking to produce high-quality printed items.

Whether you're starting a business in custom apparel or just looking for a new hobby, DTF can be a great resource. You have the power to bring any design to life, on almost any material you can think of.

DTF Transfer Components

When choosing a DTF printer, it's important to look at what you need. Printers vary in size, speed, and how much they can print at one time.

Smaller printers are good for those just starting out or with limited space. They're more affordable but can't handle as much volume.

On the other hand, larger printers are perfect for businesses looking to produce a lot of items quickly. They cost more and take up more space, but they can print faster and more efficiently.

So think about how much you plan to print and how quickly you need it done.

DTF Inks and Films

The quality of your prints depends a lot on the inks and films you use. High-quality DTF inks are key for vibrant and lasting prints.

They should be able to stick well to the transfer film and not fade over time.. There are a lot of brands out there, so it pays to do some research and maybe test a few to see which ones work best for your needs.

The same goes for DTF films. The film needs to be strong enough to hold the ink and adhesive. But it also needs to be flexible enough to transfer smoothly onto your fabric.

Again, testing different films can help you find the best one for your DTF projects.

Selecting the Right Adhesive Powder

The adhesive powder is what makes the design stick to the fabric. It needs to match the type of fabric you're printing on for the best results.

Some powders are better for lighter fabrics, while others are made for heavier materials.

The right powder should melt and bond well without making the fabric too stiff. It's also important to apply the right amount.

Too little, and the design won't stick. Too much, and the print might feel rough. Experimenting with different types and amounts of powder can help you get the perfect finish.

Choosing the right DTF transfer options can feel overwhelming at first. Yet, taking the time to understand these components can make a big difference in the quality and durability of your prints.

With the right equipment and materials, you can create prints that are not only beautiful but also long-lasting.

DTF for Apparel vs. Other Projects

Direct to Film transfers are a fantastic way to add personal touches to clothing. Whether it's t-shirts, hoodies, or hats, DTF can handle it all.

The beauty of DTF is in its ability to produce vibrant and detailed designs that last. This makes it ideal for anyone looking to start a clothing line or simply create unique items for their own use.

The process is straightforward. Plus, it allows for quick customization without sacrificing quality.

By choosing DTF apparel projects, you open up a world of possibilities to stand out with designs that can range from simple logos to complex, colorful patterns.

DTF Applications Beyond Apparel

DTF's versatility extends far beyond clothing. This technology can be used on a wide variety of other items. This makes it a valuable tool for many different projects.

For example, DTF transfers can be applied to bags or pillows. You can even apply them to canvas to create custom decorations or promotional items.

The ability to stick to different materials means you can explore creative projects that used to be really difficult or impossible with traditional printing methods.

Whether you're looking to personalize gifts, create custom merchandise for a brand, or even decorate interiors, DTF transfers offer the flexibility and quality to bring your ideas to life.

Tips for Maximizing Quality and Durability

To get the most out of DTF transfers, there are a few key tips to keep in mind.

First, always use high-quality materials. This includes not just the inks and films, but also the items you're transferring the designs onto. Higher-quality fabrics will result in better-looking and longer-lasting prints.

Second, pay careful attention to the application process. Following the right temperature and pressure settings is essential to make sure that the transfers adhere properly and look great.

Finally, proper care of the printed items can greatly extend their lifespan. Washing them inside out and using cold water are a good idea. Avoiding high heat when drying can help maintain the vibrant colors and sharp details of your DTF prints.

From creating custom clothing to designing unique merchandise, DTF stands out for its versatility, quality, and durability.

Troubleshooting Common DTF Transfer Issues

Working with Direct to Film transfers opens up a world of creative possibilities, but sometimes things don't go as planned. Understanding how to fix common issues can save time and resources, ensuring your projects turn out just right

Addressing Print Quality Problems

Occasionally, the prints might not look as crisp or vibrant as expected. This can be due to several reasons.

First, check the ink quality. Using high-quality DTF inks is essential for bright and lasting colors.

If the ink is old or of low quality, the prints can appear dull. Next, consider the transfer film. It's the carrier of your design to the fabric, so its quality is vital.

Make sure it's specifically designed for DTF printing and correctly aligned in the printer.

Printer settings are another area to review. Different designs and materials may require adjustments in how the printer applies the ink to the film. Taking the time to experiment with these settings can lead to significant improvements in print quality.

Ensuring Adhesive and Fabric Compatibility

The adhesive powder is what binds your design to the fabric. So, it's a critical component of the overall DTF process.

Not all fabrics react the same way to the adhesive though. Choosing the right type is important. Some powders are formulated for light fabrics, while others are better suited for heavier materials.

Testing a small amount on your fabric before starting a large project can prevent issues.

Applying the correct amount of powder is also an important component of the process. Too little, and the design might not adhere well. This can lead to peeling.

Too much powder can make the fabric feel stiff and uncomfortable. Finding the right balance is key to a successful transfer.

Maintenance Tips for DTF Equipment

Regular maintenance of your DTF equipment is essential to prevent issues. For the printer, this means keeping the print heads clean and free from ink blockages.

A clogged print head can cause missing parts of the design or poor color application. The heat press, which is used to transfer the design from the film to the fabric, also needs attention.

Make sure its plates are clean and evenly distributing heat. Uneven heat or dirt on the plates can result in poor-quality transfers.

Following the manufacturer's maintenance guide for your equipment can extend its life and improve the quality of your prints.

Troubleshooting DTF transfer issues might seem like a complex process at first. But once you get the hang of it, you'll hardly notice the effort. And troubleshooting and maintenance of these parts and components will save you a lot of grief in the long run.

The goal is to create beautiful, durable prints, and with a bit of patience and knowledge, you can achieve just that.

Future Trends in DTF Transfers

As we look ahead, the world of Direct to Film transfers is set to become even more exciting with technological advancements.

One area of innovation is in the development of eco-friendly inks. These new inks are designed to reduce environmental impact without compromising on quality or color vibrancy.

They promise a more sustainable way of producing printed materials. The industry is also working on making DTF printers faster and more efficient.

This means businesses and hobbyists alike can look forward to producing high-quality prints in less time, making it easier to meet demand or work on multiple projects.

Expanding Applications of DTF Transfers

The potential applications for DTF transfers are broadening too. Beyond apparel, we're seeing an increased use of DTF technology in creating custom merchandise, home decor, and even vehicle wraps.

This expansion is driven by the versatility and durability of DTF prints. As the technology continues to improve, it opens up new possibilities for creative projects.

Imagine customizing not just t-shirts but chairs, bags, and even outdoor signs. And doing it with the same level of detail and color intensity!

The ability to apply DTF transfers to a wider range of materials is set to revolutionize how we think about personalized items.

The Role of DTF in Sustainable Printing

Sustainability is becoming increasingly important in all areas of production, and DTF printing is no exception.

The move towards more eco-friendly inks and materials is just the beginning. There's a growing focus on developing processes that use less energy and produce fewer waste products.

These changes not only help protect the environment but also make DTF printing a more attractive option for businesses and consumers looking for green alternatives.

As we move forward, the role of DTF in promoting sustainable printing practices is likely to become even more significant.

Getting the Best DTF Transfers in 2024

Now you have a better sense of the ways to make the best DTF transfers in 2024 and beyond! And the promise of even better DTF transfers becomes clearer, ensuring that the quest for the best DTF transfers continues to inspire and revolutionize personalized printing projects.

With DTF Transfers Wholesale, you can discover top-quality direct-to-film, DTF transfers at unbeatable wholesale prices. Benefiting from significant cost savings on bulk orders, our DTF transfers are your solution for efficient, high-volume production with stunning results. Contact us to place your bulk order and transform your printing possibilities today

Leave a comment